Why Industrial Facilities Require Superior Waterproofing

Industrial roof waterproofing is the single most critical investment for protecting a facility’s structural integrity, operational continuity, and asset value. Water intrusion is a direct threat, and high-quality waterproofing systems do more than stop leaks—they are essential for preserving the building’s core structure and ensuring long-term business success. For over 50 years, Heritage Roofing & Repair has specialized in protecting commercial and industrial facilities across Northwest Arkansas with proven waterproofing solutions.

Safeguarding Structural Integrity and High-Value Assets

The primary reason industrial facilities need robust industrial roof waterproofing is to protect their core. Water infiltration is an insidious enemy, silently compromising the very bones of your building. It can lead to steel beams rusting, concrete decks spalling, and wooden structural elements rotting. These issues don’t just look bad; they reduce the load-bearing capacity of your roof and walls, potentially leading to catastrophic structural failures. Effective waterproofing acts as an impenetrable shield, halting this deterioration before it starts, preserving the structural integrity that supports your entire operation.

Beyond the structure itself, industrial facilities house high-value assets—expensive machinery, sensitive electronics, raw materials, and finished goods. A single roof leak can damage or destroy these assets, leading to significant financial losses. Imagine a leak dripping onto a control panel or a critical production line. The cost of repair or replacement, coupled with the interruption to your business, can be staggering. High-quality industrial roof waterproofing prevents these scenarios, ensuring your valuable investments remain dry and functional.

Maintaining Operational Uptime and Safety

In the world of industrial operations, downtime is a dirty word. Leaks can force immediate production shutdowns, leading to missed deadlines, unfulfilled orders, and significant revenue loss. The ripple effect can impact supply chains and damage your company’s reputation. A robust waterproofing system ensures your facility remains operational, protecting your bottom line and maintaining business continuity.

Furthermore, water on floors creates dangerous slip hazards for employees, increasing the risk of accidents and potential liability. Electrical systems are also highly vulnerable to water damage; a leak near wiring or equipment can lead to short circuits, power outages, or even fires. A dry, secure facility is not just about asset protection; it’s fundamental to maintaining a safe working environment and ensuring the well-being of your team. By preventing water intrusion, industrial roof waterproofing directly contributes to higher productivity and a safer workplace, allowing your operations to run smoothly and without interruption.

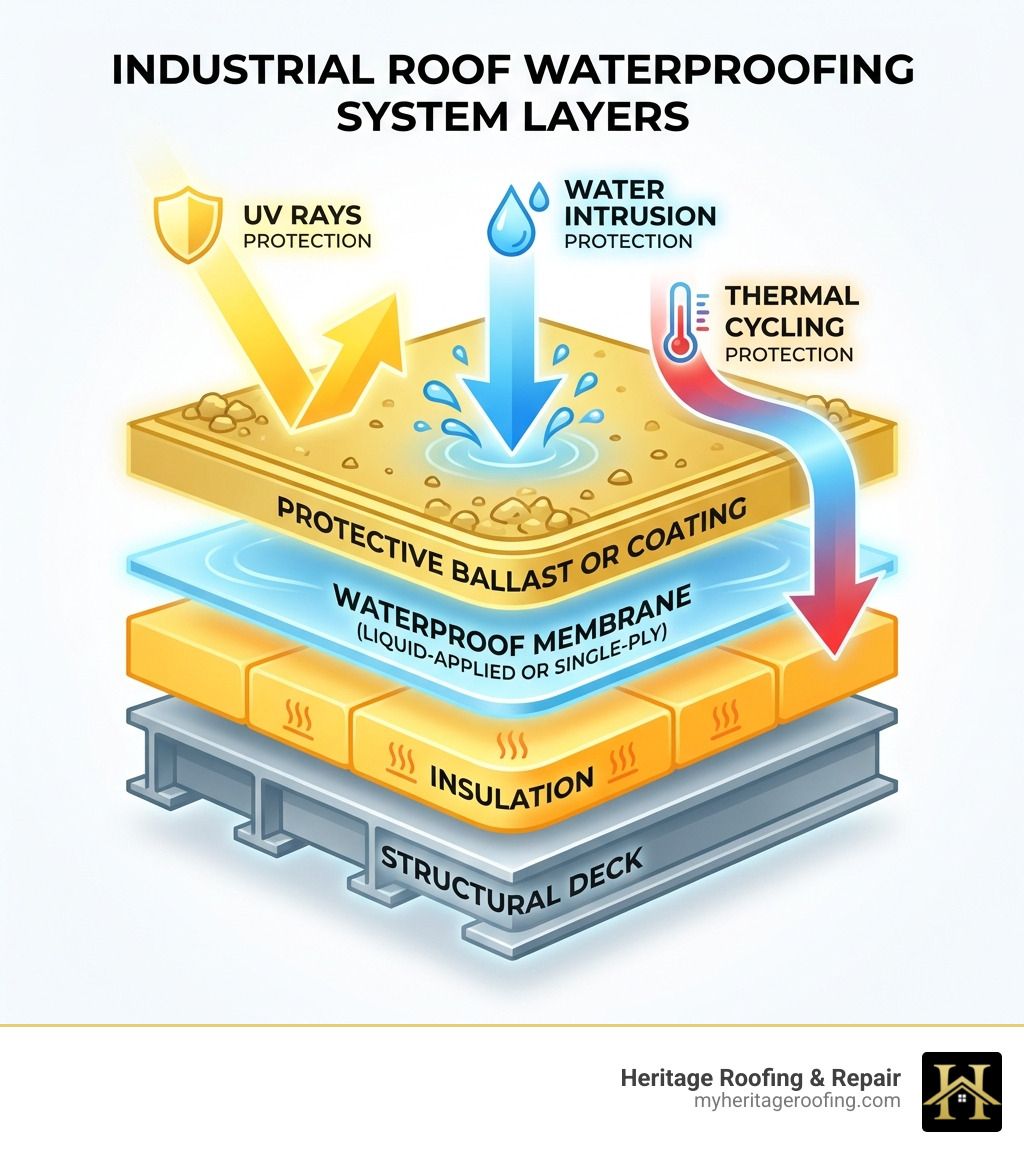

Leading Types of Industrial Roof Waterproofing Systems

Selecting the optimal industrial roof waterproofing system depends on your roof’s type, existing condition, local climate (like the heavy rainfall we sometimes see in areas like Harrison, AR), and any specific environmental factors such as chemical exposure or heavy foot traffic. Modern systems offer seamless, durable, and long-lasting protection, with some designed to last over 30 years. We pride ourselves on recommending solutions that can withstand extreme elements and provide superior protection for decades, much like those developed with over 60 years of experience in every imaginable climate.

Here’s a comparison of the leading types of industrial roof waterproofing systems:

| System Type | Durability | Cost (Initial) | Installation | Best Use Case |

|---|---|---|---|---|

| Liquid-Applied Membranes (Coatings) | 10-25+ years (with reapplication) | Moderate | Quick, minimal disruption, seamless | Complex roofs with many penetrations, existing roofs needing restoration, energy efficiency goals (cool roofs), irregular shapes. |

| Single-Ply Membranes | 20-30+ years | Moderate to High | Fast (factory-welded), clean, less labor-intensive | Large, open roof areas, new construction, reroofing, where consistent quality and strong puncture resistance are critical. |

| Modified Bitumen | 15-25+ years | Moderate | Torch-applied or self-adhered, multi-ply | High-traffic roofs, roofs with minor structural movement, excellent resistance to punctures and tears, cold-weather flexibility. |

Liquid-Applied Membranes (Roof Coatings)

Liquid-applied systems, often referred to as roof coatings, are a versatile and increasingly popular choice for industrial roof waterproofing. These products are applied as a liquid, curing to form a seamless, monolithic membrane that adheres directly to the substrate. This makes them ideal for complex roofs with numerous penetrations, such as vents, pipes, and HVAC units, where traditional sheet membranes might struggle to provide a watertight seal. The continuous, joint-free surface eliminates common leak points, offering superior protection.

We often recommend these systems because of their adaptability and performance. For example, silicone roof coatings are extremely UV stable and highly reflective, which can significantly reduce cooling loads, lower utility bills, and improve indoor comfort in our warm Arkansas summers. Acrylic roof coatings are another cost-effective option, also offering high UV resistance and reflectivity, though they perform best on roofs with positive drainage. Urethane roof coatings are among the strongest and most durable elastomeric coatings available, forming a rugged yet elastic surface resistant to punctures and abrasions.

The elastomeric properties of these coatings mean they can stretch significantly, often up to 300% of their original size. This flexibility allows them to accommodate the natural expansion and contraction of the roof due to temperature fluctuations, preventing cracks and maintaining their integrity over time. For more in-depth information on selecting the right coating, explore our Commercial Roof Coating Guide.

Single-Ply Membrane Roofing

Single-ply membrane roofing systems are another excellent choice for industrial roof waterproofing, known for their durability and consistent quality. These systems consist of large, flexible sheets of synthetic polymer materials that are manufactured in a factory, ensuring uniform thickness and composition. Once on-site, these sheets are rolled onto the roof and either mechanically fastened, fully adhered with adhesive, or ballasted.

The most common types we see in industrial settings include:

- PVC Roofing (Polyvinyl Chloride): Known for its strength, chemical resistance, and ease of heat-welding, creating incredibly strong, factory-welded seams. This significantly reduces the need for on-site seaming, meaning less labor and fewer potential leak points, a benefit backed by over 60 years of manufacturing expertise in PVC solutions.

- TPO Roofing (Thermoplastic Polyolefin): A popular choice due to its excellent reflectivity, energy efficiency, and resistance to UV radiation and punctures. Like PVC, TPO seams are heat-welded, forming a monolithic, watertight bond.

- EPDM Roofing (Ethylene Propylene Diene Monomer): Often referred to as “rubber roofs,” EPDM is a durable, flexible, and relatively inexpensive option, particularly good for large, low-slope roofs.

A key advantage of single-ply systems is their robust scrim reinforcement. These membranes feature strong reinforcement scrims, often with a density of 18 by 14, 18 by 9, or 9 by 9 polyester threads per inch, providing superior resistance to punctures and tears. This makes them highly resilient to foot traffic and environmental stressors.

Modified Bitumen Roofing

Modified Bitumen roofing is an advanced evolution of traditional built-up roofing (BUR) systems, offering improved flexibility and durability for industrial roof waterproofing. It incorporates polymers into asphalt, creating a rubberized asphalt product that is more resilient to temperature extremes and structural movement. With over 100 years of manufacturing expertise in bituminous solutions, this technology has proven its worth.

Modified Bitumen membranes are typically installed in multiple layers, often with a torch-applied method (though self-adhering or cold-applied options are also available for safety and convenience). The “modified” aspect comes from the addition of polymers:

- SBS-modified (Styrene-Butadiene-Styrene): This rubberized polymer gives the membrane elasticity and flexibility, particularly in colder temperatures, making it less prone to cracking.

- APP-modified (Atactic Polypropylene): This plasticized polymer provides excellent UV resistance and heat-aging performance, making the membrane more pliable at higher temperatures.

These multi-ply systems create a formidable, robust barrier against water intrusion. Their inherent strength and flexibility make them an excellent choice for roofs that experience minor structural movement or are subjected to heavy foot traffic.

The Essential Process: Assessment, Installation, and Maintenance

A successful industrial roof waterproofing project requires a meticulous process, from initial evaluation to ongoing care. Skipping any step can compromise performance, reduce the system’s lifespan, and ultimately lead to costly failures. A professional roof inspection is the critical first step in ensuring your investment is sound.

Assessing Your Industrial Roof for Waterproofing Needs

Before we recommend any solution, a thorough assessment of your industrial roof’s current condition is paramount. This evaluation helps us determine whether a simple coating, a repair, or a full replacement is the most appropriate and cost-effective approach. Our professionals carefully evaluate key indicators of roof health:

- Moisture Surveys: These surveys use specialized equipment to detect trapped moisture within the roof system. If the moisture survey reveals that 25% or more of the roof area contains moisture, a complete tear-off is typically required before new waterproofing can be applied.

- Core Cuts: We perform a minimum of three core cuts for the first 100 squares and one core cut per additional 100 squares. These small sections of the roof are removed and analyzed to verify existing roof conditions, identify the layers of the roof system, and determine precisely where moisture is present.

- Ponding Water: Any area of the roof that holds water for more than 48 hours after precipitation stops is considered ponding water. This is a major concern as it accelerates membrane degradation and indicates drainage issues.

- Seam Separation: For existing membrane systems, we inspect all seams for signs of separation, lifting, or deterioration, which are common entry points for water.

- Rust and Corrosion: For metal roofs, areas of concern include rust, compromised fasteners, dented/damaged panels, excessive gaps, and open ridge vents. For non-metal roofs (TPO, PVC, EPDM, modified bitumen), we look for signs of surface degradation, punctures, or brittleness.

- Substrate Condition: We ensure that existing substrates are clean, completely dry, and free of any debris before application of any liquid-applied products. The roof must have positive drainage.

For expert assessment of your industrial roof in Berryville, Fayetteville, or Harrison, contact our local team:

Heritage Roofing & Repair

3458 Arkansas State Hwy 221, Berryville, AR 72616

(870) 654-1164

Proper Installation and Proactive Maintenance

Once the right industrial roof waterproofing system is chosen, proper installation is absolutely critical. Even the highest quality materials will fail if not installed correctly. Certified installation by experienced professionals like our team at Heritage Roofing & Repair is essential not only for optimal performance but also for ensuring your warranty remains valid.

Key aspects of proper installation include:

- Substrate Preparation: This is often the most overlooked yet vital step. All surfaces must be clean, dry, and free of contaminants, debris, or loose materials. Any necessary repairs to the existing roof deck must be completed before waterproofing begins.

- Positive Drainage: Ensuring the roof has a proper slope to prevent ponding water is fundamental. If existing drainage is inadequate, solutions like tapered insulation or crickets may be necessary.

- Seam Treatment: For membrane systems, seams must be carefully welded or adhered according to manufacturer specifications. For liquid-applied systems, the seamless application naturally eliminates seam issues.

- Flashing Details: Roof penetrations, parapet walls, and other details are common areas for leaks. Proper flashing, often reinforced with fabric or specialized sealants, is crucial to create a watertight seal around these complex areas.

After installation, the job isn’t over. A proactive roof maintenance plan is essential to maximize your investment and extend the life of your industrial roof waterproofing system. This includes:

- Regular Inspections: We recommend at least twice a year (spring and fall) and after any significant weather events (common here in Arkansas!). Inspections should check for surface degradation, compromised seams/joints, clogged drainage systems, and damaged flashings.

- Debris Removal: Accumulated leaves, branches, and other debris can trap moisture, promote vegetation growth, and damage the roof membrane. Regular cleaning helps maintain drainage efficiency.

- Prompt Repairs: Addressing minor issues like small punctures or seam gaps as soon as they are detected is vital. If left unattended, small problems can quickly escalate into major concerns and expensive repairs.

Long-Term Value: Financial and Sustainability Benefits

Investing in high-quality industrial roof waterproofing delivers benefits that extend far beyond simply preventing leaks. It’s a strategic decision that offers significant financial savings and contributes to your facility’s sustainability goals. The financial implications of neglecting your roof are severe: costly structural repairs, damaged inventory, and disruptive operational downtime far exceed the initial investment in proactive waterproofing.

Energy Efficiency and Sustainability

Modern industrial roof waterproofing systems, particularly “cool roof” coatings, play a pivotal role in boosting energy efficiency. Coatings like silicone and acrylic are highly reflective, meaning they bounce a significant portion of the sun’s UV rays and heat away from the building. This dramatically reduces solar heat absorption, which in turn lowers the demand on your HVAC systems.

The benefits are tangible:

- Lower Utility Bills: By keeping the building cooler, air conditioning units work less, leading to substantial reductions in energy consumption and lower utility costs. Silicone, for instance, is extremely UV stable and highly reflective, making it excellent for reducing cooling loads.

- Improved Indoor Comfort: A cooler roof translates to a more stable and comfortable indoor environment for your employees and sensitive equipment.

- Extended Roof Lifespan: Roof coatings can add service years to an existing roof, giving you time to budget and plan for a future replacement on your timeline. This also means fewer roof replacements over the building’s lifetime, reducing the amount of waste sent to landfills and supporting environmental sustainability.

- Reduced Urban Heat Island Effect: Reflective roofs help mitigate the urban heat island effect, where metropolitan areas are significantly warmer than surrounding rural areas.

These systems contribute to a greener footprint for your industrial facility. Durable roofing solutions for warehouses and industrial facilities often emphasize these energy-saving and sustainable features.

The Importance of Warranties

When making a significant investment in industrial roof waterproofing, the warranty offered is a critical component of your decision-making process. A robust warranty reflects a manufacturer’s and installer’s confidence in their product and workmanship. We always advise our clients to seek comprehensive, long-term No Dollar Limit (NDL) warranties. These warranties, often spanning 15 to 30 years, are invaluable because they cover both materials and labor for the entire system, not just individual components.

However, it’s crucial to understand that these best-in-class warranties typically require installation by a Certified Roofing Contractor. Certification ensures that the contractor has undergone specific training and adheres to the manufacturer’s strict installation guidelines, which is essential for the system to perform as intended and for the warranty to remain valid. We are proud to be certified for leading manufacturers, ensuring our clients receive the best possible protection.

Furthermore, look for warranties that include premium consequential damage coverage, as well as hail and/or high wind protection—especially relevant for businesses in areas like Northwest Arkansas prone to severe weather. Understanding your Roofing Warranty in detail before making a final decision is paramount to protecting your investment for the long haul.

Protect Your Facility with Expert Waterproofing Solutions

Industrial roof waterproofing is one of the most important investments for any facility. It is a critical safeguard that prevents structural failure, protects high-value assets from damage, and eliminates costly operational disruptions. Beyond mere leak prevention, modern waterproofing systems significantly improve energy efficiency, contribute to a more sustainable operation, and improve the overall value and longevity of your industrial building. By understanding the diverse range of available systems, ensuring meticulous and certified installation, and committing to a proactive maintenance schedule, you can secure your building’s future for decades to come.

If your industrial roof shows signs of wear, if you’re experiencing leaks, or if you’re simply ready to invest in long-term, comprehensive protection for your facility, don’t hesitate to consult the experts. At Heritage Roofing & Repair, we bring over 50 years of experience and a reputation for dependable, high-quality craftsmanship to every project across Berryville, Fayetteville, and Harrison, Arkansas. We’re ready to help you steer the best industrial roof waterproofing solutions for your specific needs. Learn more about our commercial roofing services, schedule a comprehensive roof evaluation, or contact us today.