Why TPO Dominates 40% of the Commercial Roofing Market

Thermoplastic Polyolefin (TPO) roofing commands an impressive 40% of the commercial roofing market, and it’s easy to see why. This single-ply membrane offers a powerful combination of durability, energy efficiency, and affordability. For business owners seeking a reliable, long-lasting solution, professional TPO roof construction is a leading choice. At Heritage Roofing & Repair, we’ve seen how a properly installed TPO system protects commercial investments across Northwest Arkansas.

A TPO system’s strength comes from its multi-layer design. The membrane features a UV-resistant top layer, a reinforced middle, and a flexible bottom layer. When fused with heat-welded seams, these systems can last 15 to 30 years. However, the success of any project depends on the skill of the installer. The expertise of a trusted commercial roofing contractor is non-negotiable to prevent seam failures and ensure longevity.

What is TPO Roofing? A Look at the Components and Layers

TPO, or Thermoplastic Polyolefin, is a single-ply roofing membrane renowned for its reliability in the commercial market. It’s engineered by combining polypropylene and ethylene-propylene rubber with a tough polyester scrim reinforcement. This composition gives TPO its flexibility to handle temperature changes while resisting UV rays and chemicals.

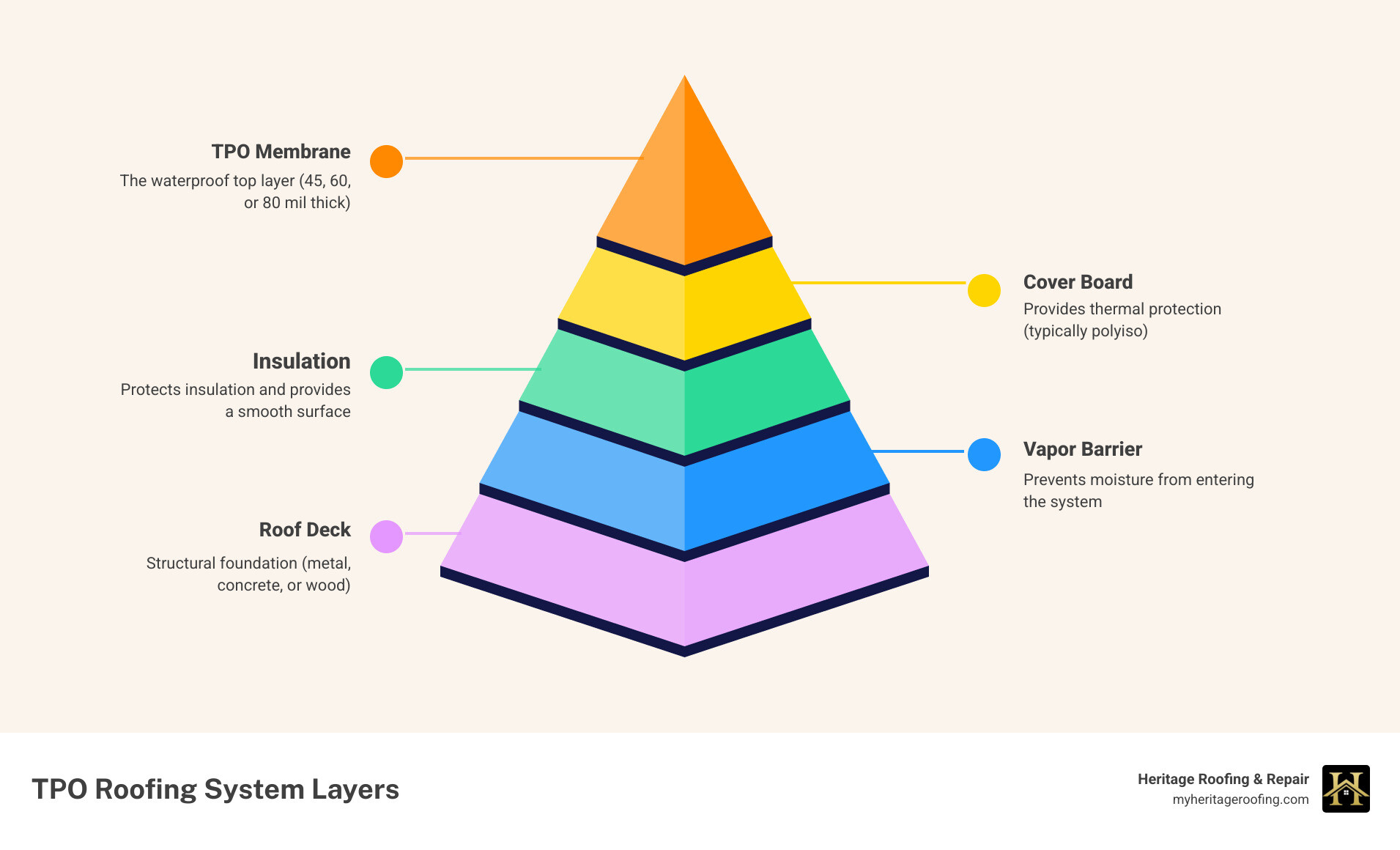

A proper TPO roof construction is a complete system, not just a single sheet. Each layer works in concert to protect your building, starting from the foundation up:

- Roof Deck: The structural base of the roof, which can be metal, concrete, or wood. It must be clean, dry, and sound before work begins.

- Vapor Barrier: In certain climates, a vapor barrier is installed to prevent moisture from inside the building from compromising the roofing system.

- Insulation: Typically Polyisocyanurate (Polyiso) boards, this layer is key for energy efficiency and controlling heating and cooling costs.

- Cover Board: This gypsum layer protects the insulation from damage, distributes loads, and provides a smooth, stable surface for the membrane.

- TPO Membrane: The final, waterproof shield. This layer, reinforced with polyester, protects your building from the elements while its reflective surface helps lower energy costs.

For more details on how we design the right system for your property, see our TPO Roofing services.

TPO Membrane Thicknesses and Sizes

Choosing the right membrane thickness is crucial for durability and longevity. Thickness is measured in mils (one-thousandth of an inch).

- 45-mil (0.045″): An entry-level option suitable for low-traffic roofs, though less common today due to durability concerns.

- 60-mil (0.060″): The industry standard, offering an excellent balance of performance and cost for most commercial applications.

- 80-mil (0.080″): The heavy-duty choice, providing maximum puncture resistance for roofs with heavy foot traffic or in harsh weather environments.

TPO membranes come in large rolls, typically 10 or 12 feet wide, to minimize the number of seams, which reduces potential leak points and speeds up installation.

The Complete TPO Roof Construction Process

Proper TPO roof construction is a systematic process where precision at every step ensures a durable, watertight result. The difference between a good roof and a great one lies in the details, from initial prep to final inspection.

- Substrate Preparation: The process begins with a clean, dry, and structurally sound roof deck. All debris is removed, and any underlying moisture issues are addressed, often using infrared inspections to locate hidden problem areas.

- Insulation and Cover Board Installation: These layers provide thermal protection and a stable base. They are secured using either mechanical fasteners or specialized adhesives, depending on the system.

- Membrane Placement and Welding: Large TPO sheets are unrolled and positioned with precise overlaps. The seams are then fused using robotic heat-welding equipment, creating bonds that are stronger than the membrane itself. This technique is critical for seam integrity, especially at T-joints where three sheets meet.

- Detailing and Flashing: Every pipe, vent, and wall transition is a potential weak point. We use custom-fabricated TPO flashing and pre-molded accessories to create seamless, waterproof seals around all penetrations.

- Quality Control: A final inspection of every seam and connection verifies that the entire system is installed to our exacting standards and performs as designed.

Key TPO Roof Construction Installation Methods

The versatility of TPO roof construction allows for several installation methods to fit different building needs and budgets.

- Mechanically Attached: The membrane is secured to the deck with screws and plates, often along the seams. This is a reliable and cost-effective method detailed in the installer’s guide.

- Fully Adhered: The membrane is bonded to the substrate with a powerful adhesive, creating a smooth, seamless appearance. This detailed installation process is ideal for roofs where aesthetics are a priority.

- Induction Welded (RhinoBond®): This advanced method uses electromagnetic induction to weld the membrane to special plates. It offers superior wind uplift resistance and is popular for high-performance applications, as shown in its technical specifications.

Why Choose TPO? Advantages, Costs, and Energy Efficiency

TPO has earned its top spot in commercial roofing by delivering an best combination of performance, value, and long-term savings. Its heat-welded seams create a monolithic, waterproof barrier with exceptional puncture resistance. Beyond its durability, TPO’s cost-effectiveness and energy-saving cool-roof benefits make it a smart investment for any business owner.

Understanding TPO Roofing Costs: What to Expect

TPO roof construction is one of the most budget-friendly options, typically costing between $6 to $12 per square foot installed. The final price depends on several factors:

- Roof size and complexity

- Condition of the existing roof (tear-off vs. overlay)

- Building height and access

- Type and thickness of insulation

- Membrane thickness (60-mil is standard)

- Installation method (mechanically attached, adhered, or induction welded)

- Warranty level

A significant factor in the final cost is whether the existing roof can be recovered (or overlaid) versus requiring a full tear-off. A recover, where the new TPO system is installed over the old roof, can save on labor and disposal costs. However, this is only an option if the existing roof is structurally sound, dry, and has only one layer, as building codes typically prohibit more than two roofing layers. A thorough inspection, including infrared scans for hidden moisture, is necessary to determine if a recover is a viable and safe option.

TPO vs. Other Single-Ply Membranes: EPDM & PVC

| Feature | TPO (Thermoplastic Polyolefin) | EPDM (Ethylene Propylene Diene Monomer) | PVC (Polyvinyl Chloride) |

|---|---|---|---|

| Cost | Generally cost-effective, mid-range. | Often the most budget-friendly upfront. | Typically the most expensive upfront. |

| Lifespan | 15-30 years with proper maintenance. | 20-30+ years, known for long life. | 20-30+ years, excellent durability. |

| Seam Strength | Heat-welded seams (chemical bond) are very strong (3-4x EPDM). | Adhered with tape or liquid adhesives; can be a point of failure. | Heat-welded seams are extremely strong. |

| Energy Efficiency | Excellent reflectivity (especially white TPO), high SRI. | Dark color absorbs heat (unless white-coated). | Excellent reflectivity (especially white PVC), high SRI. |

| Repairability | Relatively easy with heat welding. | Patching with EPDM tape and primer. | Easy with heat welding. |

TPO strikes an ideal balance of price and performance. Its heat-welded seams are three to four times stronger than EPDM’s taped seams, providing superior protection against leaks. While PVC also has welded seams, it comes at a higher price point.

How TPO Contributes to Energy Efficiency

TPO’s brilliant white surface is a key feature for energy savings. Its high solar reflectivity bounces up to 80% of the sun’s rays away from the building, which can lower roof surface temperatures by over 50 degrees. This significantly reduces the load on your HVAC system, leading to lower cooling costs. Many TPO products are ENERGY STAR rated, qualifying them for potential rebates and tax incentives. By reducing energy consumption, TPO also helps mitigate the urban heat island effect, making it an environmentally responsible choice.

TPO Roof Maintenance, Repair, and Warranties for Longevity

A TPO roof is a durable asset, but like any major investment, it requires proactive care to maximize its lifespan. Consistent maintenance is the key to preventing minor issues from becoming costly problems.

Recommended TPO Roof Maintenance Practices

To keep your TPO roof in top condition, follow a simple but consistent maintenance schedule:

- Regular Inspections: Visually inspect your roof twice a year (spring and fall) and after any severe weather event.

- Debris Removal: Keep the surface clear of leaves, branches, and other debris that can trap moisture and cause damage.

- Drainage Cleaning: Ensure gutters and drains are clear to prevent standing water, which is a primary enemy of any roofing system.

- Seam and Flashing Checks: Pay close attention to seams, flashing, and seals around pipes, vents, and HVAC units. Look for any signs of lifting or cracking.

A professional maintenance plan is the best way to ensure small issues are caught and addressed early.

Common TPO Roof Repairs and Issues

Even with proper care, repairs may occasionally be needed. Common issues include:

- Punctures: Often caused by dropped tools or sharp debris. These are typically simple to repair if caught early.

- Seam Separation: Less common with proper installation, but can occur due to extreme weather or building movement.

- Flashing Leaks: The seals around roof penetrations are high-stress areas that may require periodic attention.

Repairs are straightforward: the damaged area is cleaned, and a new TPO patch is heat-welded into place, creating a permanent, waterproof bond.

Navigating TPO Roofing Warranties

A strong warranty protects your investment. TPO manufacturers offer some of the best in the industry, but it’s important to understand the terms.

- Types of Warranties: Options range from basic material-only warranties to comprehensive labor and material warranties. The best is a No-Dollar Limit (NDL) warranty, which covers the full cost of repairs for issues related to materials or workmanship.

- Term Length: NDL warranties typically run for 15 to 30 years, depending on the system.

- Certified Installer Requirement: To qualify for the best warranties, the roof must be installed by a manufacturer-certified contractor. This ensures the TPO roof construction meets the highest standards for long-term performance.

Your Local TPO Roofing Experts in Berryville, AR

When it comes to TPO roof construction, local expertise is critical. In Northwest Arkansas, we face a unique climate with brutal summer heat, ice storms, and severe spring weather. A roofing system must be built to handle these extremes.

At Heritage Roofing & Repair, we have over 50 years of experience installing TPO roofs that perform in our specific conditions. We know which materials and installation methods offer the best resistance to UV degradation, thermal shock, and high winds. This local knowledge is invaluable, especially when storms strike. Our team is experienced in navigating the insurance claim process, ensuring damage is properly documented to help you get your business back to normal quickly.

We are committed to our community. We’re not a storm-chasing company; we’re your neighbors, here to provide reliable service for years to come. For a partner invested in your success, choose Heritage Roofing & Repair.

Heritage Roofing & Repair

3458 Arkansas State Hwy 221, Berryville, AR 72616

(870) 654-1164

Frequently Asked Questions about TPO Roof Construction

Here are answers to the most common questions we receive about TPO roof construction.

How long does a TPO roof last?

A professionally installed TPO roof typically lasts 15 to 30 years. The final lifespan depends on factors like membrane thickness (thicker is better), local climate, quality of installation, and the level of routine maintenance.

Can you install a TPO roof over an existing roof?

Yes, this process, known as a “recover” or “overlay,” is often possible and can save on tear-off costs. However, the existing roof must be structurally sound, dry, and generally have only one previous roofing layer. Building codes typically prohibit more than two layers. We always perform a thorough inspection, including infrared scans for hidden moisture, to determine if a recover is a viable option.

Is TPO roofing environmentally friendly?

Yes, TPO is one of the greenest commercial roofing options. Its white, reflective surface significantly reduces cooling costs and energy consumption. The material contains no hazardous plasticizers, and it is recyclable at the end of its service life, which helps reduce landfill waste and qualifies for LEED points in green building projects.

Conclusion: Protect Your Investment with Professional TPO Installation

It’s clear why TPO roof construction leads the commercial roofing industry. It delivers an unbeatable package: a long lifespan, significant energy savings from its reflective surface, and superior durability thanks to heat-welded seams. This multi-layered system offers a robust, cost-effective barrier to protect your commercial property.

However, the ultimate performance of a TPO roof hinges entirely on the quality of the installation. Improper workmanship can undermine even the best materials, leading to premature failure and costly repairs. With over 50 years of experience in Northwest Arkansas, Heritage Roofing & Repair has perfected the techniques required for a flawless installation.

Your commercial roof is a critical asset. Don’t leave it to chance. For expert TPO roof construction that will protect your investment for decades, contact our team. Explore our TPO Roofing services to get started.