Flat Roof Repair in Arkansas: Why Problems Can’t Wait

Flat roof repair becomes urgent fast. Unlike sloped roofs that shed water naturally, flat systems depend on drainage and membrane integrity. In Arkansas’ storm‑prone climate, even a pinhole can escalate into rot and interior damage. Just 1 inch of ponding water adds about 5.2 pounds per square foot of weight to your roof, compounding stress with every storm. If you’re looking for a trusted roofing contractor in Northwest Arkansas, count on Heritage Roofing & Repair to assess issues quickly and fix them right.

Most flat roof repairs cost between $300-$1,000 for minor fixes, while moderate repairs range from $1,000-$2,500. The key is catching problems early before they escalate.

Flat roofs in Arkansas face unique challenges from our unpredictable weather patterns. Heavy rains, hail storms, and temperature swings can cause membrane damage, drainage issues, and structural stress. Regular maintenance becomes even more critical in our climate.

For any significant damage or if you’re unsure about the repair scope, it’s always wise to consult with experienced professionals in roof repair to ensure lasting results and prevent small problems from becoming costly disasters.

I’m Rex Wisdom, owner of Heritage Roofing & Repair, and our family has been serving Berryville and Northwest Arkansas for over 50 years. We’ve handled countless flat roof repair projects, from emergency storm damage to preventive maintenance, and understand exactly what it takes to keep these roofs performing in our challenging Arkansas weather.

Need a crew nearby? Our roofers in Harrison, AR are just a short drive away.

Visit or call our Berryville office

Heritage Roofing & Repair

3458 Arkansas State Hwy 221, Berryville, AR 72616

Phone: (870) 654-1164

How to Spot Flat Roof Damage Before It Leaks

Your flat roof works hard every day, silently protecting your property from Arkansas weather. But like any hardworking system, it eventually shows signs of wear. The trick is catching these warning signals before they turn into expensive emergencies.

Arkansas weather can be particularly tough on flat roofs. Our heavy spring rains, summer heat, winter freezes, and occasional hail storms create the perfect storm for roofing problems. When you know what to look for, you can spot trouble early and save yourself from major headaches down the road.

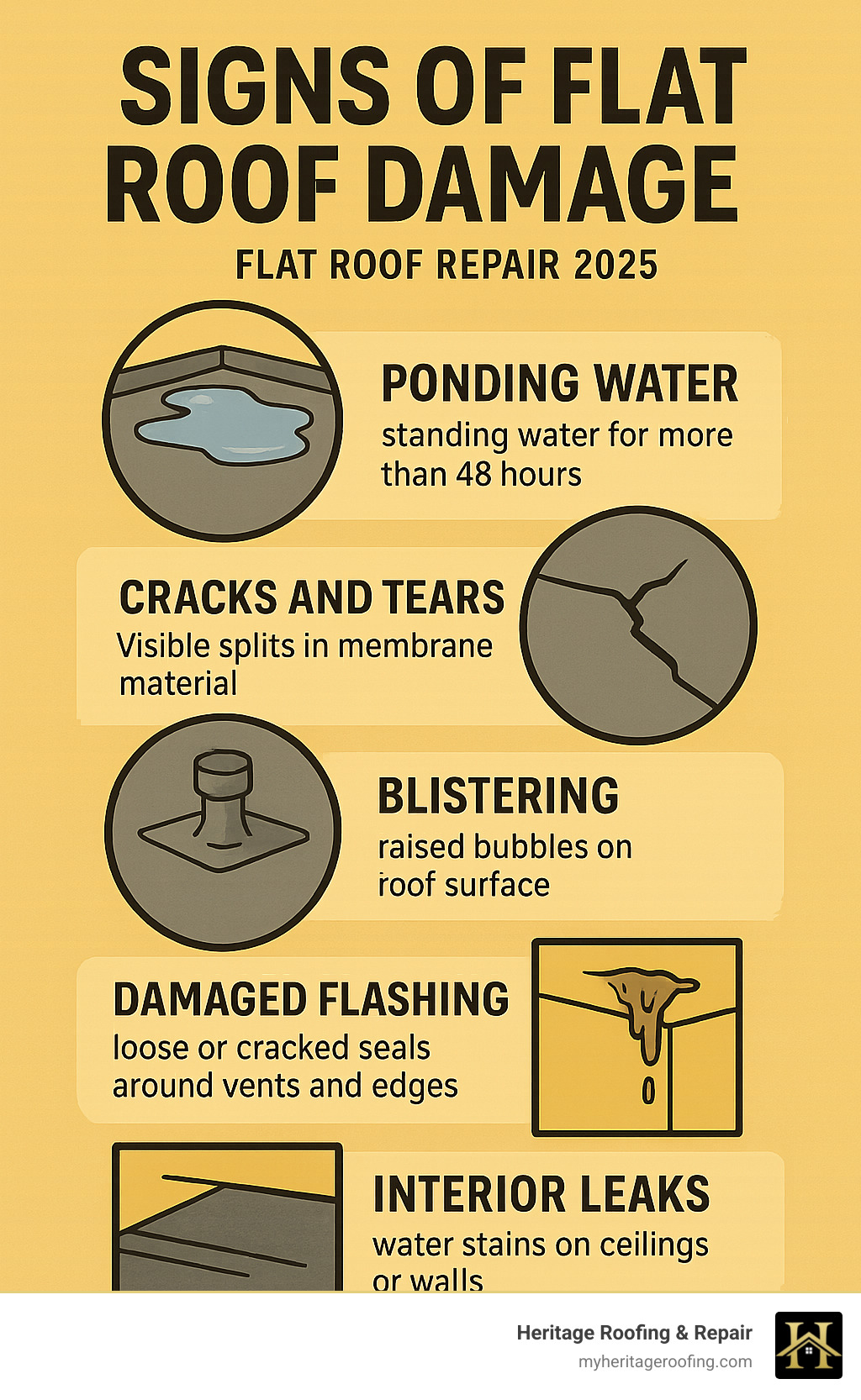

Ponding water is probably the biggest red flag. If water sits on your roof for more than 48 hours after rain, that’s a problem waiting to happen. Blistering and bubbling on the surface means moisture has gotten where it shouldn’t be. Visible cracks, splits, or tears in the membrane are like open doors for water damage.

Other warning signs include punctures from debris, sagging areas that suggest structural issues, and damaged flashing around vents and edges. Inside your building, watch for water stains, peeling paint, musty odors, and unusually high energy bills that might indicate compromised insulation.

When severe weather strikes, our storm damage roof repair expertise becomes crucial for getting your property protected quickly and properly.

Interior Warning Signs of a Failing Flat Roof

Sometimes your roof sends distress signals from the inside first. These interior clues often appear before exterior damage becomes obvious, making them incredibly valuable for early detection.

Water stains on ceilings and walls are the classic giveaway. Those telltale brown or yellowish patches, especially after a rainstorm, mean water has found its way through your roof membrane. Don’t ignore even small stains – they have a way of growing fast.

Musty odors are another dead giveaway. That persistent damp smell, particularly on upper floors, signals moisture accumulation and potential mold growth. Trust your nose on this one – it’s often right.

When you start seeing visible mold growth – those black, green, or white fuzzy patches on ceilings or walls – you’ve got a serious moisture problem that needs immediate attention. Peeling interior paint or wallpaper happens when water intrusion causes surfaces to lose their grip.

High humidity levels that seem unexplained, especially upstairs, can indicate a slow roof leak that’s allowing moisture to seep in gradually. And of course, dripping water is the most alarming sign – when you see actual drops, the leak is active and significant.

Exterior Red Flags That Demand Immediate Attention

A walk around your building can reveal problems before they show up inside. These exterior warning signs are your early warning system for flat roof repair needs.

Ponding water that lasts over 48 hours tops the list. While flat roofs have a slight slope for drainage, water that overstays its welcome puts tremendous stress on your membrane and accelerates deterioration.

Cracks or splits in the membrane create direct pathways for water. These can develop from UV exposure, extreme temperature swings, or normal building movement. Blisters or bubbles on the surface form when moisture or air gets trapped beneath the roofing material. They expand and contract with temperature changes, eventually bursting and creating leaks.

Damaged flashing around vents, chimneys, or roof edges breaks the watertight seal that keeps water out of penetrations. Debris accumulation from leaves, branches, and other materials can trap moisture and block drainage systems.

Clogged drains or scuppers prevent proper water flow off your roof. When drainage fails, water accumulates, leading to ponding and potentially dangerous structural overload.

Regular roof inspections help catch these issues while they’re still manageable. The earlier you spot problems, the less they’ll cost to fix and the longer your roof will last.

Flat Roof Materials Compared: Lifespans, Repair Costs, and Fix Methods

Not all flat roofs are created equal. Understanding what type of roofing material covers your building is crucial for effective flat roof repair. Each material has its own personality, quirks, and specific repair needs. Modern flat roofing systems often outperform older materials in durability, energy efficiency, and ease of repair.

The roofing industry has come a long way over the past few decades. While older systems like built-up roofing served their purpose, today’s single-ply membranes offer strong performance and longer lifespans. However, we still encounter plenty of traditional systems that need attention.

Here’s what you need to know about the most common flat roofing materials:

| Material Type | Longevity (Years) | Cost (Repair/Sq Ft) | Repair Method | UV Resistance |

|---|---|---|---|---|

| EPDM | 15-25 | $4-$7 | Adhesive patches, seam sealing | Good |

| TPO | 15-20 | $5-$8 | Heat welding, adhesive | Excellent |

| PVC | 20-30 | $6-$10 | Heat welding, solvent bonding | Excellent |

| Modified Bitumen | 10-20 | $3-$6 | Torch-down, cold adhesive | Fair |

Single-ply membranes like TPO, PVC, and EPDM have become the gold standard for modern flat roofing. These systems consist of large sheets that are mechanically attached, fully adhered, or ballasted to the roof deck. They’re easier to install, repair, and maintain compared to older multi-ply systems.

Traditional systems like built-up roofing and modified bitumen are still common, especially on older commercial buildings. These multi-layer systems can be more complex to repair but often provide excellent waterproofing when properly maintained.

Fire safety is a critical consideration for any flat roof system. The NRCA fire safety recommendations provide valuable guidance on material selection and installation practices. This is particularly important for commercial buildings where fire codes are strictly enforced.

Repairing Modern Single-Ply Membranes (TPO, PVC, EPDM)

Modern single-ply membranes are generally easier to repair than traditional systems, but each type requires specific techniques and materials.

TPO (Thermoplastic Olefin) roofs are popular for their energy efficiency and durability. When repairing TPO, heat welding is the gold standard for permanent fixes. Small punctures can be patched with TPO membrane pieces and appropriate adhesives. Seam failures are common issues that require professional attention to ensure proper heat-welded repairs.

PVC roofs offer excellent chemical resistance and longevity. Repair techniques are similar to TPO, using heat welding for permanent repairs and solvent bonding for certain applications. PVC is particularly good at self-healing minor punctures, but larger damage requires professional patching with compatible materials.

EPDM (rubber) roofs are known for their flexibility and weather resistance. Unlike TPO and PVC, EPDM repairs typically use adhesives and sealants rather than heat welding. Small holes can be patched with EPDM patches and contact cement. Seam failures are the most common issue with EPDM systems and require careful cleaning and re-sealing with appropriate primers and sealants.

All single-ply systems are vulnerable to punctures from foot traffic, falling debris, or mechanical equipment. The key to successful repairs is using compatible materials and following manufacturer specifications for surface preparation and application.

Fixing Traditional Built-Up & Modified Bitumen Roofs

Traditional flat roofing systems require different repair approaches and safety considerations compared to modern membranes.

Modified Bitumen systems consist of reinforced asphalt sheets that are either torch-applied or installed with cold adhesives. We often encounter blisters, cracks, and seam failures. Small repairs can be done with roofing cement and patches, but larger areas may require torch-down application – which carries significant fire risks and should only be handled by trained professionals.

Built-Up Roofing (BUR) systems, also known as tar and gravel roofs, consist of multiple layers of asphalt and reinforcing materials topped with gravel or other surfacing. These systems are durable but can develop alligatoring cracks – a pattern of interconnected cracks that resembles alligator skin. Repairs typically involve removing damaged sections and rebuilding with multiple layers.

Cold-applied adhesives have become increasingly popular for traditional system repairs because they eliminate fire risks associated with torch-down methods. These systems cure through solvent evaporation rather than heat application, making them safer for occupied buildings.

The biggest challenge with traditional systems is that repairs often require multiple layers and longer cure times. However, when done properly, these repairs can last for decades and provide excellent waterproofing performance.