Why Invest in a Commercial Roof Coating System?

Commercial roof coating is a liquid-applied protective membrane that transforms your existing roof into a seamless, waterproof barrier. As a cornerstone of the trusted roofing solutions we provide in Northwest Arkansas, these advanced polymer systems offer building owners a cost-effective alternative to expensive roof replacement while delivering superior protection and energy efficiency.

What is Commercial Roof Coating?

- Fluid-applied membrane that cures into a seamless protective layer

- Elastomeric properties allow stretching and contracting without damage

- Monolithic system eliminates weak points and potential leak sources

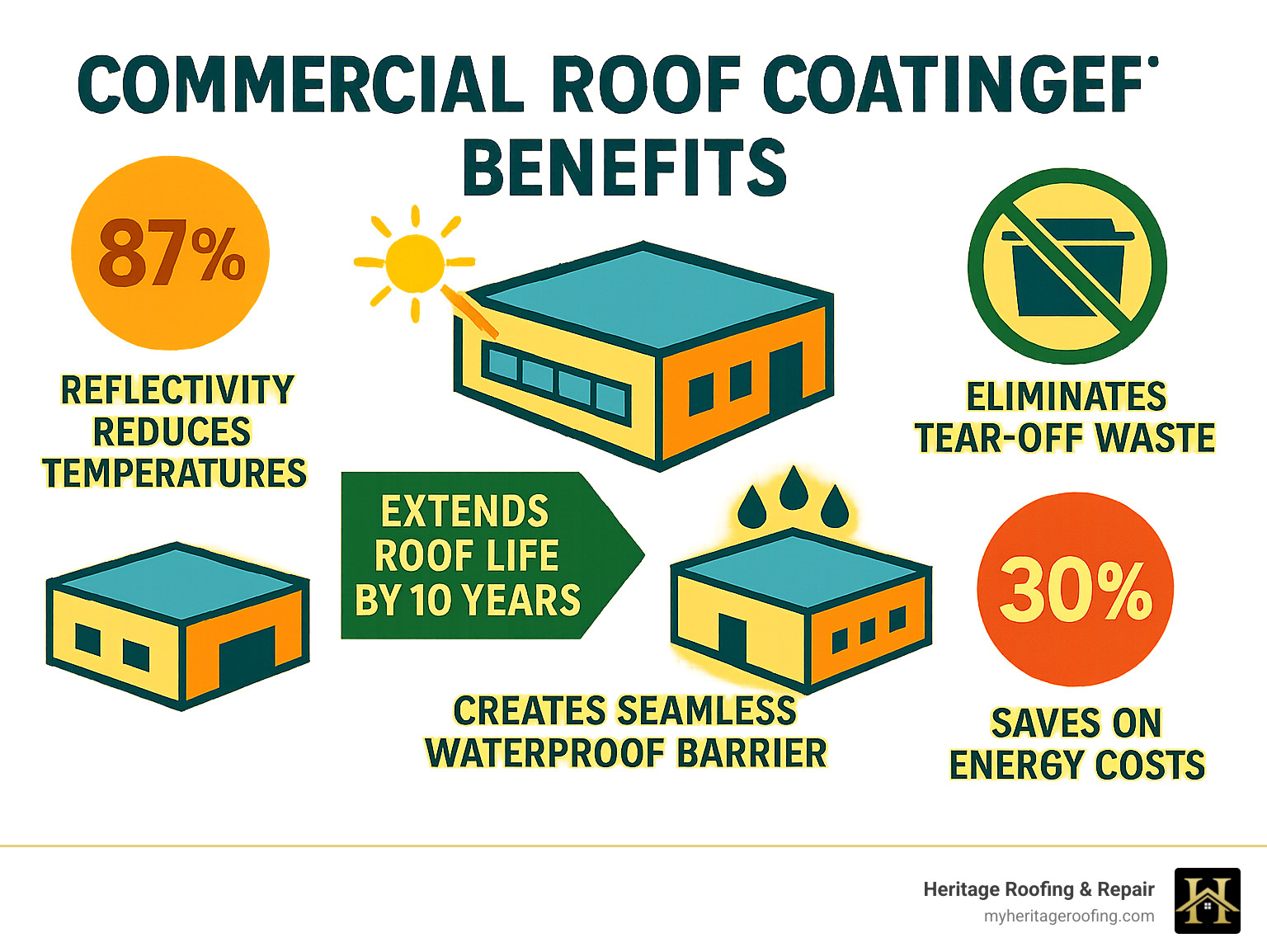

- Reflective surface reduces energy costs by up to 30%

- Extended lifespan of up to 10 additional years for existing roofs

Key Benefits:

- Extends roof life by up to a decade

- Reduces energy costs through high reflectivity (87% initial reflectivity)

- Eliminates need for costly tear-off and replacement

- Provides seamless waterproof protection

- Minimal business disruption during application

Commercial roof coatings have become one of the most popular roofing solutions because they address multiple problems simultaneously. Whether your building faces ponding water, UV damage, or aging membrane issues, the right coating system can restore your roof’s performance while delivering significant cost savings.

I’m Rex Wisdom, owner of Heritage Roofing & Repair, and our family has been providing trusted roofing solutions throughout Arkansas for over 50 years. Our expertise in commercial roof coating systems has helped countless businesses extend their roof life while reducing energy costs and avoiding expensive replacements.

When we talk about commercial roof coatings, we’re discussing a transformative solution for your building’s most vital protective layer. It’s not just about stopping leaks; it’s about making a smart, long-term investment in your property’s future. Let’s explore why these systems are gaining so much traction.

Extend Your Roof’s Lifespan by up to a Decade

Imagine adding years, even decades, to the life of your existing commercial roof. That’s precisely what a high-quality commercial roof coating can do. Applied properly, a commercial roof coating may extend the life of your roof by up to 10 years, and some advanced systems can even add up to 25 years to a roof’s service life. This isn’t just wishful thinking; it’s a proven outcome.

These coatings form a robust, protective layer that shields your roof from the elements that cause degradation over time. Think of it as a super-powered sunscreen and raincoat for your building. They effectively block harmful UV rays, which are a major culprit in breaking down roofing materials. By preventing this constant assault from the sun, the coating significantly slows down the aging process of your roof’s membrane. This proactive approach postpones the need for a costly full roof replacement, saving you substantial capital expenses.

Beyond UV protection, these coatings offer excellent resistance to weathering, dirt pick-up, and general wear and tear. They maintain their integrity through varying temperatures and harsh weather conditions, keeping your roof resilient. This not only extends the functional life of your roof but also preserves its aesthetic appeal. It’s a win-win for both your budget and your building’s curb appeal. We believe in proactive maintenance, and you can learn more about it on our page dedicated to proactive roof maintenance.

Slash Energy Costs with a “Cool Roof”

One of the most compelling advantages of commercial roof coating systems is their remarkable ability to boost your building’s energy efficiency. Many commercial roof coatings are designed to be highly reflective, turning your roof into a “cool roof.” What does that mean for your bottom line? A lot!

These coatings boast high initial reflectivity values, with some elastomeric commercial grade roof coatings providing an impressive 87% initial reflectivity, which settles to a still excellent 77% weathered reflectivity. This means that a significant portion of the sun’s energy is bounced back into the atmosphere rather than being absorbed by your roof.

The result is a dramatically lower rooftop temperature. For instance, studies have shown a 35°C (95°F) heat reduction on a modified bitumen roof with a white, reflective roof coating compared to an uncoated section. An infrared image vividly illustrated this, showing an uncoated (black) section of a modified bitumen roof at a scorching 79°C (174°F), while the coated (white) section was a comfortable 26°C (79°F).

This reduction in roof temperature directly translates to a cooler interior for your facility. When your roof stays cooler, your building’s air conditioning system doesn’t have to work as hard to maintain comfortable indoor temperatures. This reduces the strain on your HVAC system, leading to significant energy savings and lower utility bills. It’s like giving your air conditioner a much-needed vacation! The U.S. Environmental Protection Agency (EPA) has extensively researched the benefits of cool roofs in reducing urban heat islands and energy consumption. You can find more information on their findings via EPA’s research on Cool Roofs.

A Sustainable and Cost-Effective Choice

In an era where sustainability and smart financial decisions go hand-in-hand, commercial roof coating systems stand out as an environmentally friendly and economically sound choice. The most significant environmental benefit is the elimination of the need for a full roof tear-off. Traditional roof replacements often involve tearing off the old roofing material, which then ends up in landfills. Applying a commercial roof coating eliminates this waste, lowering the overall environmental impact of the project. It’s a fantastic way to reduce your building’s carbon footprint.

From a cost perspective, the savings are substantial. While the roof coating cost will depend on the type of polymer you use, you are improving your existing roof installation instead of replacing it, bringing significant savings into your budget. Restoring a roof is much more cost-effective than all other roofing options, including a complete replacement. This means you can allocate your capital to other critical business operations or improvements.

Furthermore, the application process for commercial roof coatings is typically less disruptive than a full roof replacement. They do not require expensive heavy equipment and will not impact your business operations as much as a tear-off and re-roof might. This minimal disruption means less downtime for your business, allowing you to continue operations smoothly while your roof is being revitalized. We understand the importance of managing your budget, and you can learn more about understanding roof restoration costs on our site.

Common Roof Issues Solved by Coatings

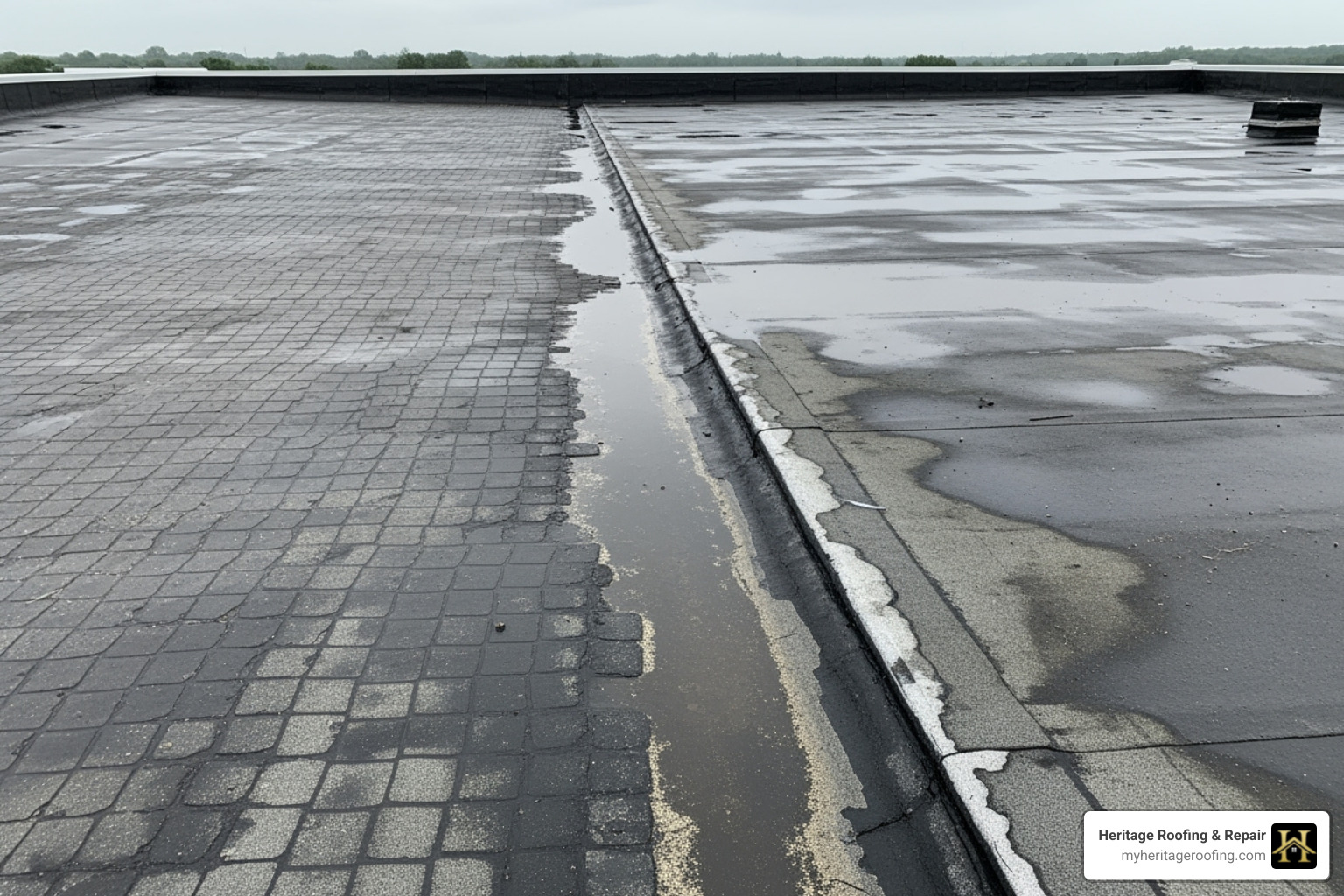

Commercial roofs, especially flat or low-slope systems, are prone to specific problems over their lifespan. From the relentless sun to pooling water, these challenges can quickly lead to costly damage. Fortunately, a commercial roof coating is engineered to directly address these vulnerabilities, turning a problematic roof into a durable, long-lasting asset.

We’ve seen it all: roofs that look like they’ve seen better centuries, riddled with cracks and leaks. But with the right coating, many of these issues can be resolved without resorting to a full replacement.

Creating a Seamless, Waterproof Barrier

One of the primary reasons commercial roofs fail is the integrity of their waterproof layer. Leaks often begin at seams, penetrations, or areas where the membrane has deteriorated. A commercial roof coating forms a monolithic, fully adhered, fluid-applied roofing membrane. This means it cures into a single, continuous layer that perfectly conforms to your roof’s shape, eliminating the weak points inherent in traditional roofing systems with multiple seams.

This seamless barrier is incredibly effective at solving roof leaks on most roofing materials. It seals existing cracks and splits, preventing water from seeping into your building. For example, on metal roofs, coatings can fix leaks and avoid costly removal, reinforcing seams on modified bitumen roofs to prevent leaks, and even sealing pinholes and hairline cracks in single-ply membranes.

For roofs prone to ponding water – those annoying puddles that seem to linger forever after a rain – coatings can offer a solution. While many roof coatings are not rated or warranted for ponding water, it’s crucial to note that some polyurethane and silicone roof coating manufacturers will warranty their products for ponding water. This makes them excellent choices for flat roofs where water accumulation is a persistent issue.

Combating Sun Damage and Aging

The sun, while essential for life, is a relentless enemy of your commercial roof. UV radiation causes roofing materials to break down, leading to a host of problems. One common issue is “alligatoring,” where the coating hardens, crackles, and becomes rough, resembling an alligator’s hide. Another is “delamination,” where the rubber coating shrinks and pulls away from other materials due to constant sun exposure and temperature fluctuations.

A high-quality commercial roof coating provides exceptional UV stability, directly combating these issues. It acts as a sacrificial layer that absorbs the brunt of the sun’s harsh rays, protecting the underlying roof membrane. This prevents alligatoring and stops delamination in its tracks. By reflecting sunlight and preventing heat absorption, coatings also protect your roof from thermal cycling – the repeated expansion and contraction caused by temperature swings, which can stress and damage materials over time.

These coatings are formulated to protect your roof from damage caused by exposure to all elements, including sunlight, rain, wind, and snow. For instance, white roof coatings can significantly extend the service life of spray foam roofs by protecting them from UV degradation, which otherwise causes them to turn orange and degrade. It’s like giving your roof a permanent, high-performance shield.

Choosing the Right Type of Commercial Roof Coating

Not all coatings are created equal. The best choice for your property depends on your specific roof type, climate, and performance goals. Understanding the key differences between the primary types of coatings is crucial for making an informed decision. Think of it like choosing the right tool for the job – you wouldn’t use a hammer to drive a screw, right?

| Feature | Acrylic Coating | Silicone Coating | Polyurethane Coating |

|---|---|---|---|

| Ponding Water Resistance | Not ideal; can re-emulsify | Excellent; often warranted | Good to Excellent; often warranted |

| UV Stability | Excellent; highly reflective | Excellent; highly reflective | Good to Excellent; often requires UV-stable topcoat |

| Durability/Flexibility | Good; elastomeric | Excellent; remains flexible | Excellent; high abrasion resistance |

| Cost | Most cost-effective | Mid-range to higher | Higher |

Acrylic Commercial Roof Coating

Acrylic coatings are a popular choice, primarily because they are water-based, highly reflective, and relatively cost-effective. They offer excellent UV resistance and are particularly effective at reflecting solar energy, contributing to those desirable “cool roof” benefits we discussed earlier.

However, acrylic coatings typically do not include warranties for ponding water. This is because they are water-based and can re-emulsify (return to a liquid state) if exposed to standing water for prolonged periods. For this reason, they are generally best suited for sloped roofs where water drains quickly. If you have a flat roof with persistent ponding issues, an acrylic coating might not be your best bet without proper drainage solutions.

Silicone Commercial Roof Coating

Silicone coatings are moisture-cured, meaning they react with moisture in the air to form a durable membrane. Their standout feature is their superior ponding water resistance. Unlike acrylics, silicone coatings are hydrophobic, meaning they repel water and will not re-emulsify even when submerged for extended periods. This makes them an excellent choice for flat roofs where standing water is unavoidable.

Beyond water resistance, silicone coatings boast high UV stability, resisting dirt and mildew, and remaining flexible over a wide range of temperatures. They are often considered one of the best options for commercial roof coating due to their overall performance and longevity.

Polyurethane Commercial Roof Coating

Polyurethane coatings are known for their exceptional durability and excellent abrasion resistance. This makes them ideal for commercial roofs that experience high foot traffic or are subjected to heavy equipment. They form a tough, resilient surface that can withstand significant wear and tear.

Polyurethanes offer strong adhesion to various substrates. While they are highly durable, they often require a UV-stable topcoat, as some aromatic polyurethanes can chalk or degrade when exposed to direct sunlight over time. However, aliphatic polyurethanes offer better UV stability. Like silicones, many polyurethane coatings are warranted for ponding water, making them another viable option for flat roofs.

The Application Process and Long-Term Care

Choosing the right commercial roof coating is only half the battle. Proper installation is the key to a successful roof coating system that delivers on its promises. A professional application ensures maximum adhesion and performance, delivering the long-term protection and energy savings you expect. It’s like baking a cake – you can have the best ingredients, but if you don’t follow the recipe, it might not turn out right!

The Professional Commercial Roof Coating Installation Process

Our typical installation process for a commercial roof coating involves several critical steps to ensure a flawless and durable result:

- Thorough Inspection: We begin with a comprehensive assessment of your existing roof to identify any structural issues, active leaks, or areas requiring specialized attention. This helps us tailor the coating system to your roof’s unique needs.

- High-Pressure Cleaning: This is perhaps the most crucial step for maximum adhesion. The roof surface must be carefully cleaned to remove all dirt, debris, loose gravel, oil, and contaminants. We typically use high-pressure washing to ensure the surface is pristine and ready for application.

- Surface Preparation: Any existing damage, such as cracks, splits, or deteriorated membranes, must be repaired. This might involve sealing imperfections with specialized mastics or patching materials. For certain substrates, a specific primer might be applied to improve adhesion, especially on aged single-ply surfaces or asphalt substrates to prevent bleed-through.

- Seam and Penetration Reinforcement: Roof seams and around penetrations (like HVAC units, vents, and pipes) are common points of failure. We reinforce these areas with appropriate fabric and coating materials, creating a robust, watertight seal. This is where the monolithic nature of the coating really shines, turning vulnerable spots into strong, seamless connections.

- Coating Application: The coating is then applied evenly across the entire roof surface. While it can be brush or roll-applied (with a ⅜” nap roller recommended), airless spray is often the most efficient way to apply roof coatings, especially for large commercial roofs. Airless sprayers use a hydraulic pump to atomize the coating, requiring specific pressures (e.g., 2,000-3,000 psi for elastomeric coatings) and flow rates to ensure optimal coverage and thickness.

- Curing Time: Once applied, the coating needs adequate time to cure and form its final protective membrane. Drying times vary depending on the product and environmental conditions, but generally, it’s recommended to allow at least 24 hours before walking on the roof.

The entire process is designed to be as non-invasive as possible, allowing your business to continue operations with minimal disruption.

Factors That Influence Project Cost

When considering a commercial roof coating, understanding the factors that influence the overall cost can help you budget effectively. While it’s true that applying a coating is significantly more cost-effective than a full roof replacement, several variables come into play:

- Roof Size and Complexity: Larger roofs naturally require more material and labor. Complex roof designs with numerous penetrations, parapet walls, or varying slopes will also increase the cost due to the additional detail work required for proper sealing and application.

- Existing Roof Condition: A roof in poor condition with extensive damage, deep cracks, or significant ponding water issues will require more preparation, cleaning, and repair work before the coating can be applied. This additional prep work directly impacts the labor and material costs.

- Type and Thickness of Coating: As we’ve discussed, different types of coatings (acrylic, silicone, polyurethane) have varying material costs. Silicone and polyurethane coatings, for instance, tend to be more expensive per gallon than acrylics but offer different performance benefits. The desired thickness of the coating application also affects material quantity and thus the price.

- Warranty Requirements: Longer or more comprehensive warranties often come with specific application requirements, material thicknesses, and quality assurance protocols that can add to the initial project cost but provide greater long-term peace of mind.

- Labor: The cost of skilled labor to properly prepare the roof and apply the coating is a significant factor. Professional application ensures the coating performs as intended and lasts for its expected lifespan.

Despite these variables, the savings achieved by avoiding tear-off and replacement, coupled with the long-term energy savings, make a commercial roof coating a highly advantageous financial decision.

Maintaining Your Coated Roof for Maximum Longevity

Just like any other asset, your newly coated roof will benefit from regular maintenance. While a commercial roof coating significantly reduces the need for extensive repairs, some simple steps can ensure it performs optimally for its entire lifespan:

- Annual Inspections: We recommend annual inspections by a qualified professional (like us!) to identify any potential issues early. This allows us to address minor concerns before they escalate into major problems.

- Gentle Cleaning: Periodically, your roof may accumulate dirt, debris, or biological growth. Gentle cleaning with water and a mild detergent can help maintain the coating’s reflectivity and overall performance. Avoid harsh chemicals or abrasive cleaning methods that could damage the coating.

- Prompt Repair of Any Damage: While durable, coatings can still be damaged by falling debris, severe weather events, or human activity on the roof. Promptly repairing any punctures, tears, or localized issues will prevent water intrusion and preserve the integrity of the entire system. Most coatings can be easily repaired with compatible materials.

- Re-coating Schedule: Manufacturers often provide guidelines for when a re-coat might be necessary, typically after many years of service. Adhering to this schedule ensures continuous protection and maximum longevity for your roof.

By following these simple maintenance practices, you can protect your investment and ensure your commercial roof coating system continues to deliver superior performance for years to come.

Frequently Asked Questions About Roof Coatings

We often hear similar questions from business owners considering a commercial roof coating. Here are some of the most common ones, answered to help you make an informed decision.

How long does a roof coating last?

A professionally installed commercial roof coating can last anywhere from 10 to 20 years, and some advanced systems can even extend a roof’s service life by up to 25 years. The exact lifespan depends on several factors: the type of coating used (silicone and polyurethane typically offer longer lifespans than acrylics), the thickness of the application, the local weather conditions (extreme heat, cold, or frequent storms can impact longevity), and adherence to a regular maintenance schedule. With proper care, your coated roof will continue to perform beautifully for a very long time.

Can you apply a coating over any existing roof?

Coatings can be applied to most structurally sound commercial roof types. This includes common systems like metal roofs, modified bitumen, built-up roofing (BUR), and single-ply membranes such as EPDM, PVC, and TPO roofing systems. Even existing coated roofs can often receive a new coating to extend their life.

The key is proper surface preparation, which includes thorough cleaning to ensure maximum adhesion and priming to create an ideal bonding surface. Our team always conducts a detailed inspection to determine if your existing roof is a suitable candidate for a coating system. If your roof has significant structural damage or is beyond restoration, a full replacement might be the more appropriate solution.

Is a roof coating the same as paint?

No, a commercial roof coating is fundamentally different from paint, even though both are liquid-applied. While paint is primarily for aesthetic purposes and offers minimal protection, a roof coating is a high-performance, specialized membrane designed for durability and weather resistance.

The main differences lie in their composition and properties:

- Thickness: Roof coatings are significantly thicker than paint. While paint is typically measured in a few dry mils, roof coatings can vary from approximately 0.075 mm (3 dry mils) to over 1 mm (40 dry mils), creating a much more substantial protective layer.

- Elastomeric Properties: Many roof coatings are elastomeric, meaning they are highly flexible. They can stretch and contract with the thermal movement of your roof without cracking or losing their integrity. Paint, in contrast, is rigid and prone to cracking with temperature fluctuations.

- Waterproofing: Coatings are formulated to create a durable, seamless, and waterproof barrier that protects against leaks and moisture intrusion. Paint offers very limited waterproofing capabilities.

- Purpose: A roof coating’s primary purpose is to protect, restore, and extend the life of a roof, as well as to improve energy efficiency. Paint’s main role is to provide color and a superficial finish.

A roof coating is an advanced, engineered solution for your roof, whereas paint is a decorative finish.

Protect Your Investment with a Superior Roofing Solution

As we’ve explored, a commercial roof coating is a smart, strategic investment that restores your roof, improves energy efficiency, and extends the life of your building. By creating a seamless, durable, and reflective barrier, you can solve existing problems and prevent future ones, all without the significant cost and disruption of a full replacement. It’s a testament to how far roofing technology has come, offering sophisticated solutions for common commercial challenges.

At Heritage Roofing & Repair, we pride ourselves on providing dependable, affordable, and quality craftsmanship. With over 50 years of trusted experience, we’ve helped countless businesses in Berryville, AR, Fayetteville, AR, Harrison, AR, and across Northwest Arkansas protect their investments. We understand the unique demands of commercial properties and are committed to delivering roofing solutions that stand the test of time.

If you’re ready to explore how a commercial roof coating system can benefit your property, the experts at Heritage Roofing & Repair are here to help. We provide trusted, high-quality roofing solutions for businesses in Fayetteville, AR and throughout the region.

Heritage Roofing & Repair

3458 Arkansas State Hwy 221, Berryville, AR 72616

(870) 654-1164